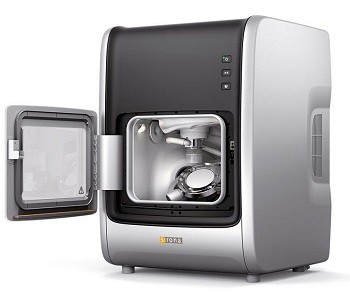

The inLab MC X5 was designed as a universal five-axis production unit to meet dental laboratory requirements for cost-efficient production. It offers your laboratory more independence in terms of material and indications as well as the processing of external CAD data. Wet/dry production unit ensures processing zirconia, polymers, composites, wax and sintering metal, as well as glass and hybrid ceramics. The inLab MC X5 is an open production unit. It is the perfect complement to the inLab

components inEos X5 and inLab software but can also be used to process other STL restoration data, including implant-supported restorations with screw access channels. Having its own CAM module, the unit can be connected flexibly to other CAD systems. The inLab MC X5 processes standard discs (ø 98.5 mm, up to 30 mm thick) and blocks in a single machine. Changing from discs to blocks takes just a few seconds. The special multi-block holder can accommodate up to six blocks of various materials,

offering maximum productivity even with multiple single-tooth restorations.